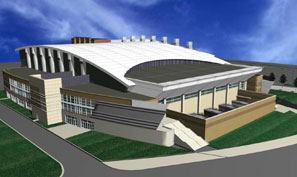

Tyson Events Center

Scott Springfield Mfg. Inc provided the main air handlers for The Tyson/IPB Events Center, a new 10,000 seat arena located in Sioux City, Iowa. The building was designed as a multi-purpose entertainment and sporting facility which includes a full-sized hockey rink with flexibility for stage performances. Two custom Scott Springfield outdoor air handlers were provided to meet very specific construction and design parameters.

Design Considerations

Designed and installed in 2003, the project required two air handlers, each delivering 75,000 cubic feet per minute (CFM). A unique operating requirement was to provide reverse airflow capability through the return air duct system if required under adverse conditions. This was achieved by providing a unique double deck configuration with the airflow path following a 180° turn from the outside air intake to the supply air discharge.

Positive pressurization into the return air duct system was then achieved through the use of dampers and a control sequence to reverse flow from the supply fans through the return duct.

The unit size was limited by an available platform area of approximately 1100 ft2. The completed units were 31.5′ wide by 34.5′ long by 22′ high. Each unit was shipped in six sections to the job site. The plan was for both units to be installed within three days. Scott Springfield provided personnel for site assistance and the contractor met his installation time on budget.

To ensure the equipment would meet the job requirements Scott Springfield Engineering personnel met with O’Connor, the rep, the consulting engineer and the contractor to review in detail, equipment serviceability, rigging and installation requirements. The designed unit has a dual supply fan stacked on top of the outside air and supply section. A staircase was provided for service within a two story unit.

The total weight of the units, consisting of six sections each is approximately 139,000 lbs. The equipment features, Ebtron GTA 116 air flow measuring station with feedback to 60 HP ABB variable frequency drives and RM Product blenders, Heatcraft heating and cooling coils and Twin City BAF Series 41 centrifugal fans.

Engineering Considerations

The location of the units presented a challenge for engineering with respect to designing the structure for uncharacteristic snow loads that were anticipated due to the positioning of the units relative to the building.

The roof and all associated structure had to accommodate an unevenly distributed snow load with one specific area of the unit supporting a load of 75 #/ft2. Since the upper section of the unit consisted of the main components, the upper section roof was designed to carry the snow loads with the lower section structurally designed to support the upper static and dynamic loads.

Due to the height of the sections, consideration was also given to the wind loads that would be experienced during transport to the jobsite.

A third structural issue considered involved how the units were to be handled in the facility and then rigged on site. Due to the physical size of each section, the optimum rigging points for handling the units in the facility were on the ends of the unit.

The unit was then designed to limit the deflection to 1/360 over a span of 31.5 feet with a four point lift. Each lifting lug was designed to carry a 20,000 pound load.

Even though AMCA certified louvers were sized at a low entering velocity, the design engineers were concerned with drifting snow entering the outside air section and melting. To address this concern, a special feature was incorporated in the outside air section. A 12″ wide by 300″ long drain system was extended full width of the section and included a removable grate to provide access for cleaning as required.

Scott Springfield Mfg Inc. has the capability to design and manufacture custom air handling equipment to meet the

requirements of the application.